What exactly is a linear fan?

Inline fan fans are a key component in many ventilation systems designed to be installed directly in duct operation. Its main function is to effectively move air from one area to another, thereby increasing airflow in a system that may be insufficient. These fans are hidden in the ducts, making them an unstriking solution to improve air circulation, remove stale air or manage temperatures in various spaces. Leveraging an inline conduit fan can significantly improve the effectiveness of your existing ventilation settings, ensuring a healthier and more comfortable indoor environment by providing consistent air movement to exactly where you need it.

Key Benefits of Using Inline Fans

Incorporating inline fans into your ventilation strategy can bring many benefits. First, they are incredibly versatile and are suitable for residential, commercial and industrial applications. They can help maintain optimal air quality by depleting pollutants, humidity and odor. When integrated into an HVAC inline fan system, they distribute heated or cooled air evenly, reducing energy costs by making your main HVAC unit work less. Furthermore, because they are installed in pipes, they usually run more quietly when airlifted compared to other fan types, thus contributing to a quieter environment. Their ability to overcome the resistance of long tubes running is an important advantage of complex ventilation layouts.

Learn about different types: axial vs. centrifugal

When choosing an inline fan, you will encounter two main designs: axial and centrifugal. The axial fan moves the air parallel to the rotation axis of the fan, similar to an aircraft propeller, and is usually suitable for high airflows with low static pressure. A common application of the axial type is as an inline exhaust fan generally ventilated in shorter pipes. In contrast, a centrifugal inline fan, also known as a squirrel cage or radial fan, draws air into the center of the fan and drains it at a 90-degree angle. These are more suitable for applications with higher static pressures, such as longer or more complex piping systems, and in this case they are often favored for their efficiency. Understanding the needs of the system will help you choose the right type.

Basic features to consider before purchasing

Several key features should guide you in purchasing an inline fan fan. Airflow capacity measured in cubic feet per minute (CFM) is crucial; you need a high CFM inline fan for larger spaces or areas that require a lot of air exchange. Noise levels, often measured in record or decibels (DBA), are another key factor, especially for residential or office environments, making quiet inline tube fans very desirable. Consider the durability of building materials, especially if the mobile air is corrosive or with particulate matter. Motor type and energy efficiency can also affect long-term operating costs. Look for features such as sealed bearings for extended life and easy maintenance and easy installation, including accessible junction boxes and a solid mounting bracket.

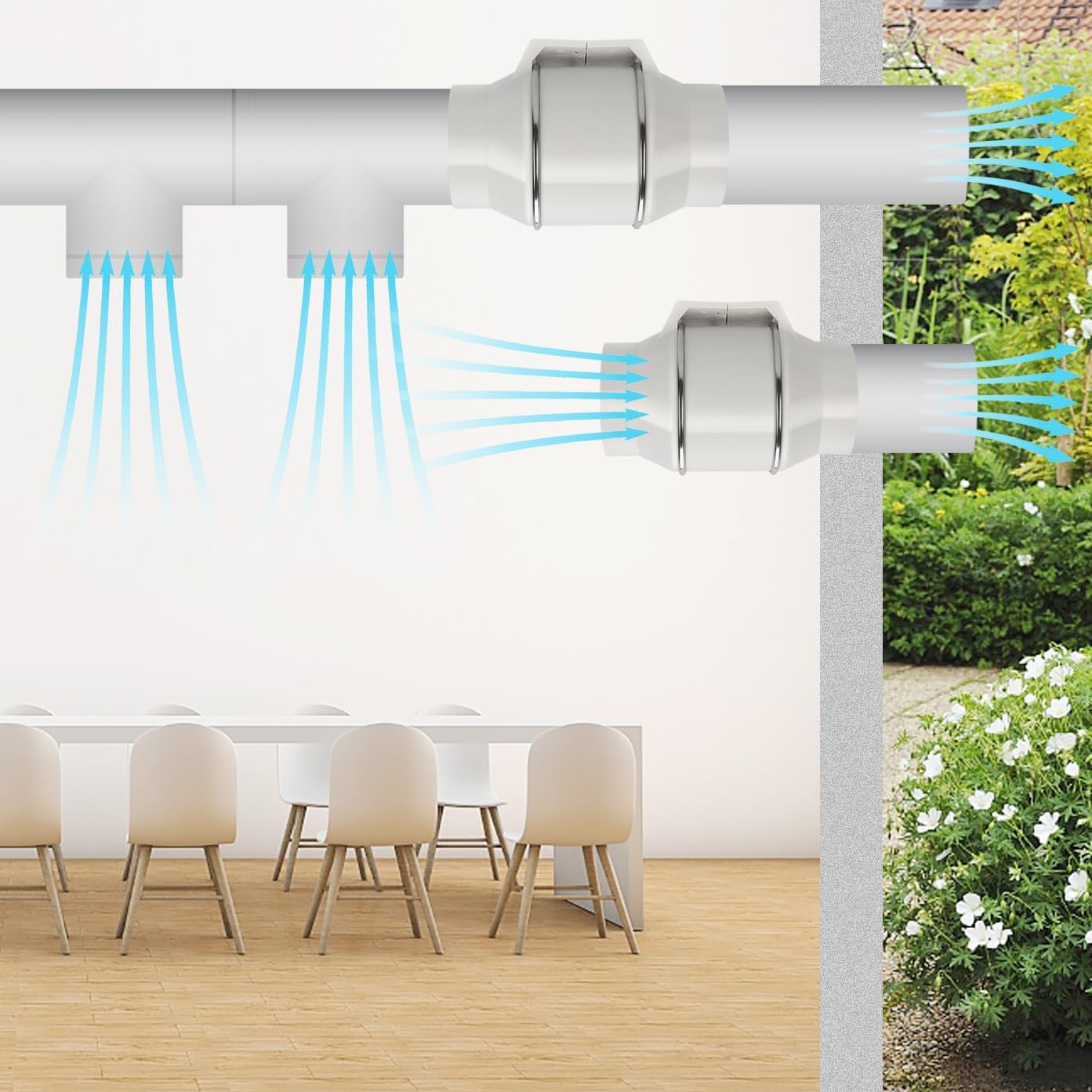

Multifunctional application: from house to industrial environment

Due to its adaptability, inline duct fans are found in various settings. In the house, they lift airflow to distant rooms, ventilated bathrooms and kitchens, or manage air in planting tents. For commercial applications, commercial inline tube fans may be essential for generally ventilated office buildings, dining room or retail spaces for exhausting kitchen smoke to maintain comfortable air circulation. On a larger scale, industrial inline pipe fans are sufficient to remove smoke, dust or chemical smoke from factories, workshops and warehouses and provide necessary air exchange in demanding environments. Their ability to tailor-made to specific airflow and pressure requirements makes them invaluable.

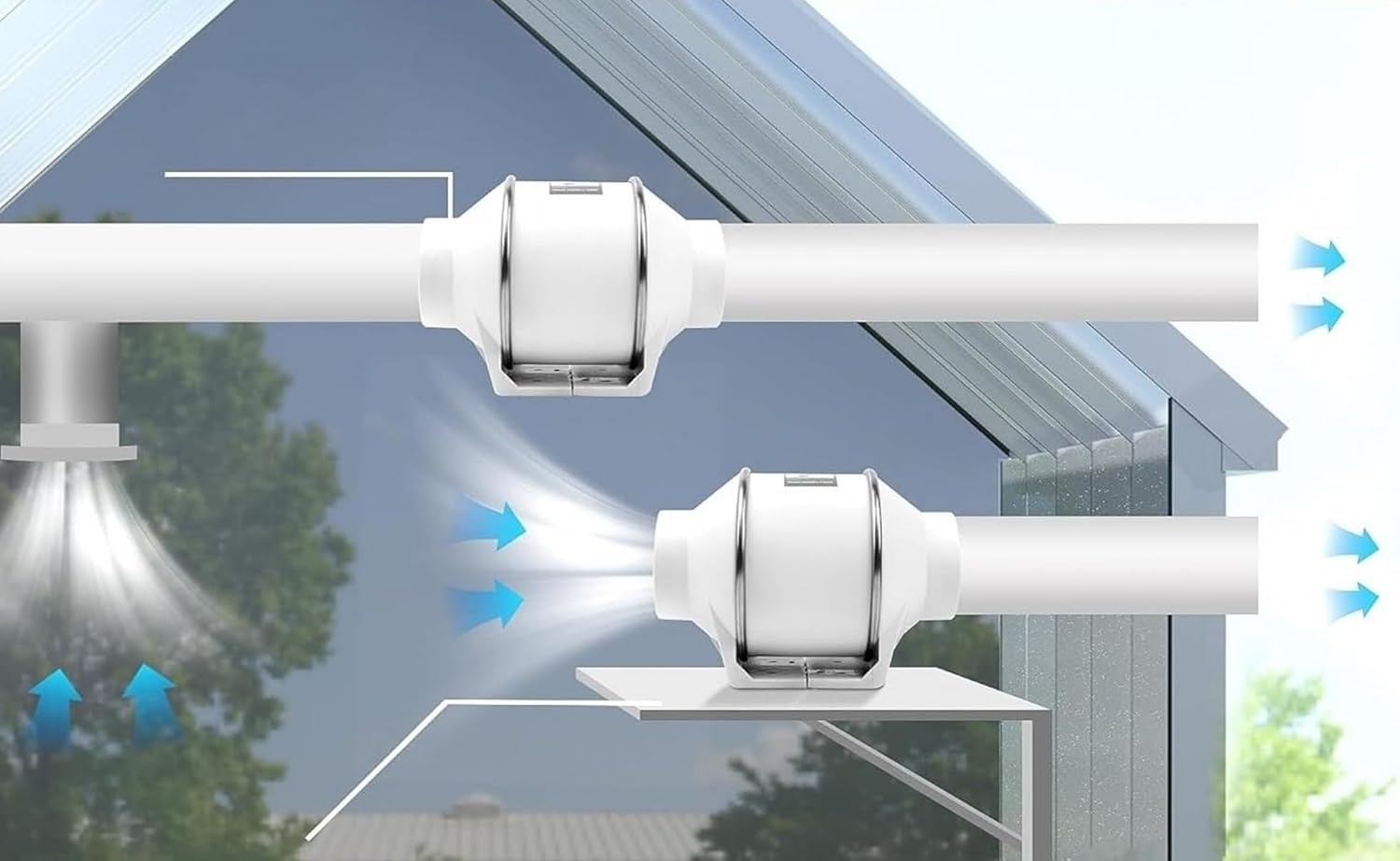

Step by step: How to install an inline pipe fan

Installing an inline fan requires careful planning and execution. Always turn off the power supply to be processed. Determine the best location in the pipeline; ensure access to future maintenance. Cut the section of the pipe that will install the fan as per manufacturer's measurement. Use appropriate clamps or tape to secure the fan to the end of the pipe to ensure a seal. If necessary, install the fan using the provided bracket to ensure it is stable and level. Next, connect the fan according to the manufacturer's instructions and local electrical code; be sure to consult a qualified electrician if you are not sure. Once installed and wired, test the fan to make sure it operates correctly, quietly, and check for any air leakage around the connection. Proper installation ensures optimal performance and security.

Professional Tips for Maintaining Inline Fan Fans

Regular maintenance will extend the life of the inline fan and maintain effective operation. Check regularly for any dust or debris on the blade and casing and gently clean with a brush or vacuum. For quiet inline fan fans, ensuring blades are clean, as buildup can lead to imbalance and noise. Check electrical connections to make sure they are safe and free of corrosion. Listen to any abnormal noise, which may indicate bearings or loose components. Make sure the pipe connections remain dense. For fans in demanding environments, such as industrial inline duct fans, more frequent inspections may be required due to stricter operating conditions. Following these simple steps can prevent expensive repairs and maintain air quality.

Work with the right ventilation experts

Choosing a right inner tube fan, whether it is a high CFM inline fan for a large workshop or a specific centrifuge inline fan for complex HVAC systems, can be a complex decision. Work with knowledgeable suppliers such as Ningbo Aoshun Electrical Co., Ltd. Provides a comprehensive ventilation solution that ensures you get expert advice and quality products. Through a dedicated focus on sourcing, designing and producing innovative electrical products, they provide wholesalers, buyers and retail customers with one-stop purchase solutions covering a wide range of fans including ventilation fans, exhaust fans and industrial fans. Their expertise can guide you with the perfect ventilation solution that meets your specific needs, ensuring efficiency and reliability in the coming years.